Sorry. We did not find anything.

Top 10 Benefits of Using Ball Bearings in Machines?

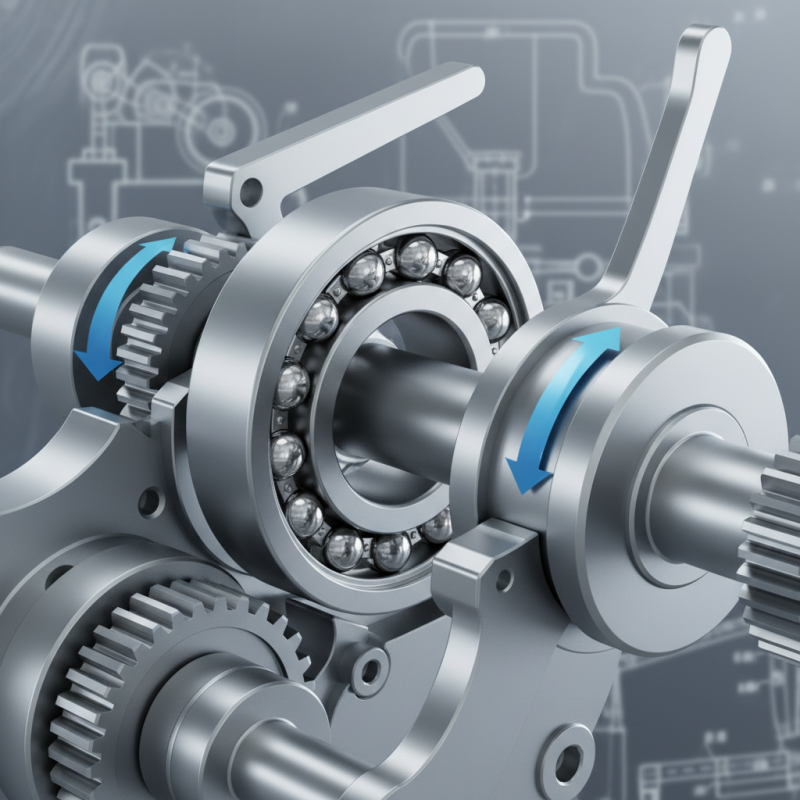

Ball Bearings play a crucial role in machinery efficiency and performance. As the industry expert Dr. Emily Thompson states, “Incorporating ball bearings can transform the way machines operate.” This statement highlights the immense benefits ball bearings provide in various applications, from reducing friction to enhancing longevity.

Utilizing ball bearings can lead to smoother operations. Machines equipped with these components often experience less wear and tear. This results in reduced maintenance costs and downtime. However, some engineers still overlook their importance. Not every machine includes ball bearings, and this can lead to inefficiencies.

Many might not realize the full potential of using ball bearings. They can significantly improve load capacity and speed, delivering substantial advantages. The choice of materials and design also influences effectiveness. Understanding these factors requires a deeper look and reflection on machine design principles.

Advantages of Reduced Friction in Machine Operation

Ball bearings play a crucial role in reducing friction in machines. This reduction leads to smoother operation and increased efficiency. By minimizing friction, energy loss decreases, allowing machines to perform better. Consider a conveyor belt. When ball bearings are used, it glides effortlessly. Without them, the belt struggles, consuming more power.

The advantages of using ball bearings extend beyond energy efficiency. They also contribute to the longevity of machine components. Less friction means less wear and tear, leading to fewer breakdowns. Imagine a fan motor; ball bearings help it spin freely. This allows for quieter operation and reduces the need for frequent repairs. However, neglecting regular maintenance can lead to failures. Dirt and grime can compromise their effectiveness, resulting in increased friction.

Another important aspect is heat generation. Ball bearings generate less heat under load compared to other types. This helps maintain optimal temperatures within the machine, preventing overheating. However, even commercial systems can sometimes overlook the importance of proper lubrication. Neglecting this can diminish the bearings’ performance, leading to excessive friction. Regular checks and balances are essential for long-term benefits.

Top 10 Benefits of Using Ball Bearings in Machines

Enhanced Load Distribution for Improved Longevity

Ball bearings play a crucial role in enhancing load distribution in machines. This is vital for extending equipment longevity. According to a report from the American Society of Mechanical Engineers, the right ball bearing can improve load capacity by up to 30%. Distributing weight evenly reduces stress concentrations. This balance leads to fewer mechanical failures.

Improved longevity is not just a benefit; it’s a necessity in many industries. Equipment downtime can cost businesses thousands of dollars. Studies show that machines with well-placed ball bearings can last 50% longer than those without them. However, improper selection can negate these advantages. If a bearing is too small for the application, it can lead to premature wear.

The design of ball bearings allows for smooth operation under various loads. The materials used, typically high-grade steel or ceramics, support this efficiency. However, it’s important to regularly check for wear. Many users overlook maintenance, thinking that bearings are self-sufficient. This oversight can lead to performance decline. Balancing efficiency and routine checks is essential for optimal performance.

Top 10 Benefits of Using Ball Bearings in Machines

| Benefit | Description | Impact on Longevity |

|---|---|---|

| Enhanced Load Distribution | Ball bearings distribute the load over a larger area, reducing stress on components. | Increases lifespan of machinery parts. |

| Reduced Friction | Ball bearings create a smoother rotation, minimizing friction between moving parts. | Lowers wear and tear, prolonging equipment life. |

| Improved Efficiency | Higher efficiency in transferring power reduces energy costs. | Contributes to lower operational costs over time. |

| Vibration Damping | Helps to absorb vibrations, preventing machinery damage. | Reduces maintenance frequency, enhancing longevity. |

| Versatility | Can be used in varying applications across industries. | Improves adaptability and extends machine lifetime. |

| High Load Capacity | Designed to handle significant radial and axial loads. | Ensures durability under heavy use. |

| Simplified Maintenance | Easy to replace and maintain, reducing downtime. | Keeps machinery running longer without extensive repairs. |

| Temperature Regulation | Help to manage operating temperatures during use. | Prevents overheating, leading to prolonged equipment life. |

| Cost-Effectiveness | Lower costs associated with repairs and energy consumption. | Provides long-term savings for businesses. |

| Noise Reduction | Reduces operational noise compared to other bearing types. | Creates a quieter working environment, enhancing user comfort. |

Increased Efficiency and Energy Savings in Mechanical Systems

Ball bearings play a crucial role in enhancing the efficiency of mechanical systems. They reduce friction, which allows machines to operate smoother. Lower friction means less energy is needed to keep parts moving. As a result, you'll notice a drop in energy costs.

Choosing the right bearing type is essential. There are various options available. Roller bearings, for example, handle heavy loads better. Consider your machine's needs carefully. Proper selection can lead to better performance and longer equipment lifespan.

Regular maintenance is a must. Inspect bearings for wear and tear frequently. This simple step can prevent unexpected failures. Replace damaged bearings promptly to maintain efficiency. Keep in mind that neglecting maintenance can lead to energy wastage and increased costs.

Simplified Maintenance and Replacement Processes for Bearings

Maintaining and replacing ball bearings can often feel overwhelming. Many machines rely heavily on these small yet vital components. Simplified maintenance can save time and money. When a bearing fails, the impact can be significant. However, with proper knowledge, addressing issues becomes easier.

One major advantage of ball bearings is their design. They allow for smooth rotation and less friction. Regular maintenance schedules can help identify wear and tear before they lead to failures. Simple tools can assist in this process. For instance, using a grease gun makes lubrication straightforward. Clear indicators of issues, such as unusual noises, demand immediate attention.

Replacement processes also benefit from the ball bearing design. With standardized sizes, replacements are often straightforward. Most bearings are easy to access in machines, reducing downtime. However, not every user has the same experience. Some may struggle to identify the right replacements. Missteps here can lead to further complications. Understanding your specific machine's needs is essential. Engaging with community resources or manuals can offer valuable insights.

Versatility in Application Across Various Industries

Ball bearings are essential in various applications across multiple industries. Their versatility allows easy integration into machines. In automotive manufacturing, ball bearings improve efficiency, helping reduce friction in moving parts. According to a report from the National Lubricating Grease Institute, ball bearings can cut energy consumption by up to 30%. This reduction in energy use not only saves costs but also promotes sustainability.

In the aerospace sector, reliability is crucial. High-quality ball bearings have enabled planes to operate safely in extreme conditions. The Aerospace Industries Association highlights that ball bearings contribute significantly to reducing maintenance downtime. This benefit is vital, as downtime can lead to significant financial losses. However, not all bearings perform equally. Variations in quality can lead to failures, necessitating careful selection for critical applications.

Even in everyday consumer products, ball bearings play a role. They enhance performance in items like bicycles and power tools. The global market for ball bearings was valued at approximately $29 billion in 2021. Interestingly, this growth also raises concerns about sustainability and waste. Many manufacturers are now focusing on eco-friendly alternatives. Nevertheless, the need for high-performance ball bearings remains, leading to ongoing innovation and challenges in the industry.